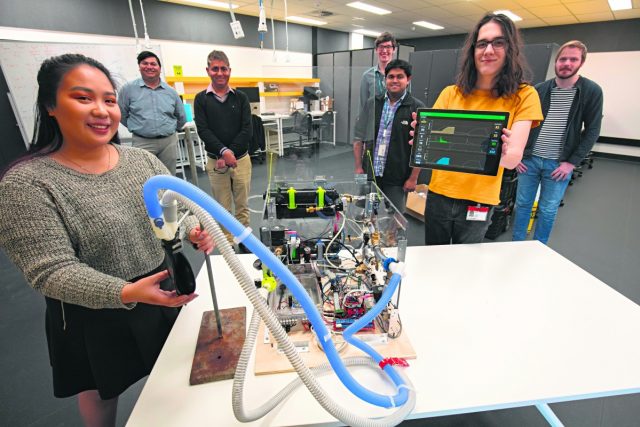

In just one week a team of 11 students and three researchers from Curtin University

worked quickly to design and develop a ventilator prototype that could potentially be used to help treat people affected by COVID-19.

The research team, with expertise across various fields including engineering, medicine and mechatronics developed an emergency ventilator device called Simple Available Ventilators for Emergency Response (SAVER).

Lead researcher Dr Tejas Bhatelia from the WA School of Mines: Minerals, Energy and Chemical Engineering said many countries are facing a shortage of ventilators and Australia may not be immune to the problem.

“Having someone very close to me, who was highly immune compromised and vulnerable to severe symptoms of COVID-19, made me think of what I can do in my capacity to help her and others in similar vulnerable health conditions,” he said.

“I am an engineer who knows how to deliver fluids and I quickly realised that ventilators were all about delivery of fluids in a controlled manner.

“Thus, I gathered a group of students and researchers to pro-actively tackle this challenge and develop SAVER.

“Although, that situation has now changed, I hope that we may never have to use SAVER on any one to save lives.”

Twenty-one-year-old student Jaci Brunning, is in her fourth year of Mechatronics

Engineering and Computer Science, and she was invited to get on board with the

project in mid-March.

“Being able to take my engineering knowledge and apply it to a new subject area with real outcomes that actually help people is what attracted me to this project,” she said.

“My experience in programming and control gave me a unique input into the

design choices of the ventilator.

“Ventilation, and indeed medical equipment in general, is a new area for us, so our research involved a wide scope not usually seen in university projects.

The SAVER ventilator is designed from the ground up, taking air and oxygen directly from the hospital (or portable compressor) and providing the suitable pressure and volume to the patient.

“One of our main features is assisted ventilation, where the ventilator provides

support without fully taking over the patient’s breathing,” Ms Brunning said.

“This allows for a wide variety of applications, as well as promoting patient recovery by weening patients off the ventilator to breathe on their own.

“Our software is designed to operate autonomously and reliably, while allowing the medical staff to monitor the ventilator both at the bed side and from a central location, such as the nurse station.

“This allows quick identification of declining patient condition, increasing response speed, especially for pandemic and trauma situations.

“This is a first-of-its-kind system that we haven’t seen anywhere else, and vastly lowers cost and increases utility of the ventilator.”

Dr Bhatelia said creating this first prototype in such a short period of time was intensive, exciting and challenging.

“We needed to make rapid decisions and had to constantly adopt our approach, as we were in middle of the crisis,” he said.

“Our key challenge was the availability of spare parts.

“Manufacture of such critical life-saving equipment locally, will open avenues for local business to re-think their business models and potentially seed a new industrial

sector in WA and Australia creating jobs of future.”